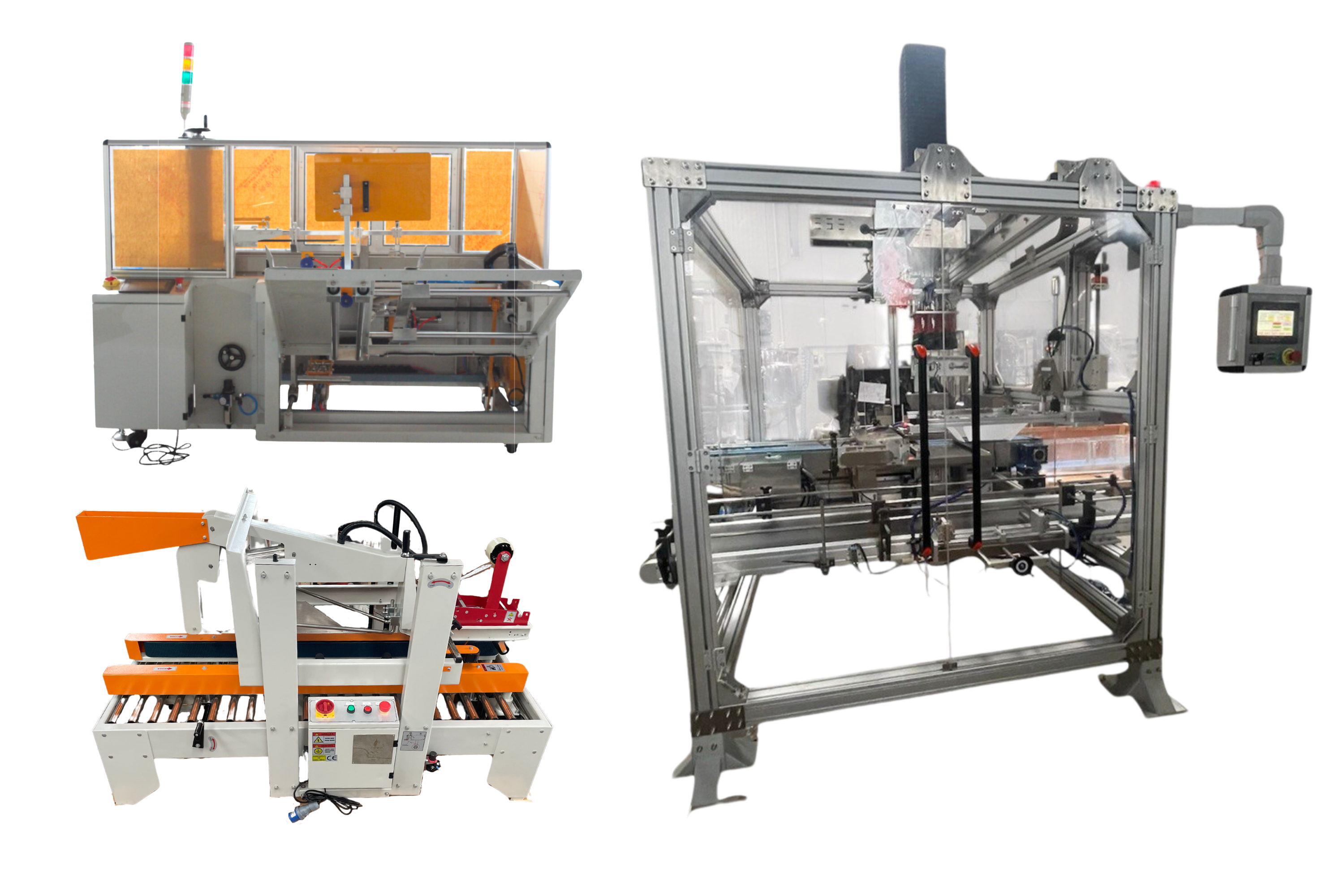

End-of-line Packaging Machines

Our end-of-line machinery provide an automated and comprehensive solution for secondary packaging, designed to optimize the final stages of production with minimal human intervention. Each system is composed of three main machines:

- Carton Erector: Using suction cups, the device picks up American-style carton blanks, forms the boxes, and automatically seals the bottom with tape, preparing the carton for subsequent filling.

- Case Packer: Equipped with a robotic arm with a pick-and-place matrix tool, it picks up a predefined number of products and places them into the carton.

- Carton Sealer: Once the products are placed into the carton by the robotic arm, the carton is automatically closed and sealed with adhesive tape, completing the packaging process.

The entire system is managed via a touch screen control panel, supported by an advanced PLC system, allowing monitoring and optimization of every stage of the process for total and intuitive control.

Advantages of DMC End-of-Line Systems

DMC’s automated end-of-line packaging systems are designed to enhance operational efficiency and minimize time and errors in secondary packaging. Each system is custom-made to meet the client’s production needs, with the ability to configure the machine to handle containers and cartons of different formats. Advanced automation ensures a continuous workflow and optimized productivity, making the industrial packaging process reliable and highly efficient.